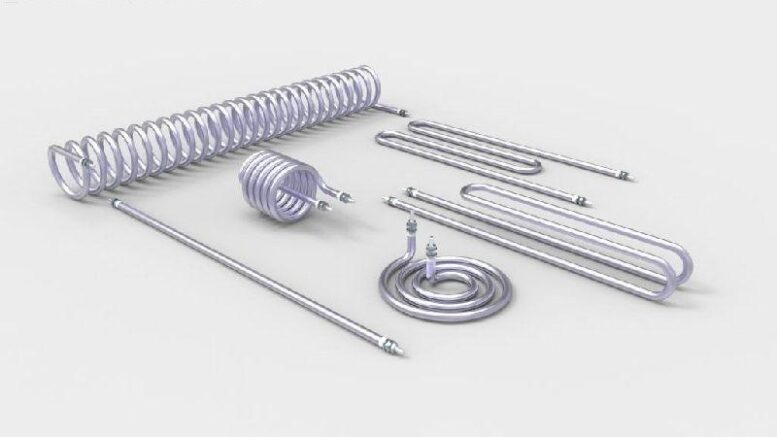

An open coil heater provides maximum heating element to a surface directly to an airflow. It exposes instant thermal response in low pressure and light weight. Open coil heating is used strategically to create custom solutions depending on what an application needs. Open coil heating elements consist of open circuits in which air is heated directly from the suspended resistive coils. Different wire gauges and wire types are used in different applications.

These are industrial heating elements that are fast to heat and have high efficiency. They can heat up to around 1,200º F at maximum.

What are tubular heaters?

Tubular elements are used in industrial heating components, which are highly adaptable to mostly electrical and mechanical heating. Tubular heaters require a more conservative design to handle higher temperatures. They can be used in different forms or shapes, like straight, bent, or however they’re needed. Whether used in free air, in a clamped space, inside proves, or into metal, they are adaptable. They are made of steel or stainless steel, copper, Incoloy and are useful in applications with up to 1,400º F.

Tubular heaters are made to provide rooms with general heat. Usually, in places where people don’t always walk in, like attics and conservatories, these are used to maintain proper temperature, especially in very cold conditions.

These are often confused with cartridge heaters. While tubular heaters can be flexible, formed into complex shapes with different lengths and diameters, innovative cartridge heaters are generally cylindrical or rectangular and cannot bend or morphed into other shapes and forms. They are only designed to be interested in drilled blind holes.

What are finned-tubular heaters?

These have similar qualities to tubular heaters. Finned-tubular heaters give out heat equal to or more than tubular ones do and can run more power over even tighter spaces. This industrial heating element is best suited for numerous applications. It can be used through convection, conduction, and radiation heat transfer to stoves, industrial ovens, dryers, and air conditioners, etc. Finned-tubular heaters can be molded into many unique forms and shapes. They are excessively rugged, inexpensive, and require little maintenance.

Open-coil vs. Tubular vs. Finned-tubular Heaters

Different heating elements influence the process of heat transfer. In order to understand more of their differences, there are some key factors to consider.

1. Air Quality and Contamination

In applications for open oil, there must be more conductive particles to contaminate the air. Both tubular and finned-tubular operations are more flexible with almost any type of air contamination. Finned tubular can handle the contamination as long as the contaminant particles don’t compromise in between the fins.

2. Airflow

Airflow influences the heat application of these three types. Finned-tubular heaters are the most tolerant regardless of inconsistent airflow in the environment. Tubular components are is less tolerant than finned-tubular and more tolerant than open-coil in uneven airflow. Open-coil heaters cannot handle inconsistent airflow and are required to have airflow uniformity in order to function properly.

3. Temperature

Open-coil and tubular heaters can be used in applications around 1,200 and 1,400º F while finned-tubular ones can heat up to 750º F given that they’re made of steel sheath and steel fins. Steel is naturally very efficient in heat transfer.

4. Thermal Response

Open-coil heaters have the fastest thermal reaction among the three types, resulting in a quick response to process control. Although it can cause inconsistent temperature by little amounts unless more control is applied.

While finned-tubular heating has a less quick thermal response, the temperature is more controllable and can lead to a uniform temperature, especially if controlled even more.

Tubular elements’ reaction varies somewhere in between open-coil and finned tubular operations.

5. Pressure

Generally, the pressure drops the less space the heater has by the elements. Open-coil heaters have the lowest pressure drop while finned tubular ones have higher. Among them, tubular elements have the highest pressure drop because there is more space occupied in the heater.

6. Shock Hazard

With accidental contact, electrical shock can be experienced with open-coil heaters since it is enclosed in a metal sheath. This feature doesn’t exist in tubular and finned-tubular heaters.

7. Application

The most reliable in heavy and severe operations are open-coil heaters since there is a bigger allowance between the live parts of the heating element and the ground. Tubular and finned-tubular heaters have fairly small spaces between the parts of the heater-the resistance wire and the sheath. Plus, they are compact with magnesium oxide, which serves as insulation.

None of these heating elements is the most efficient nor the least for application since they have their own strengths and weaknesses.

Be the first to comment on "Open-coil, Tubular, and Finned-Tubular Heaters: Which is the Most Efficient?"