What are polymer insulators?

Polymer Insulators we developed in 1950’s in order to replace a conventional ceramic insulator. These insulators were available till 1960’s, however, were refined in the following year to correct design flaws. Polymer insulators are made from fibreglass reinforced polymer rods and polymer housing. These insulators prove to be beneficial due to their cost. In addition, they also possess less weight than other materials. They were developed in Europe back in the initial years; hence Europe being known as the first primary producers of the HV polymer insulator.

The high voltage insulators are succumbed to shedding or cracking of polymer housing. This is known as chalking. The construction of basic insulator usually includes a fibreglass polymer rod, which is often referred as shed. The fitting and grounding component are made from metal.

Why choose polymer insulator over ceramic insulators?

Such ceramic insulators can withstand the elements for many years without falling. Polymer insulators possess better chances of resisting incidents of vandalism. Ceramic Insulators face frequent bonding failures, house cracks, or hardware separation and when this situation arises; water penetrates the producing voltage leakage and housing. In order to maintain these devices, you need to apply a protective coating along with occasional washing of insulators.

In order to recreate environmental conditions, there is a computer-operated machine, which simulates the weather condition in a controlled chamber. By testing the polymer in such conditions, the durability of the same is put on the test. It also helps to increase the lifespan of the polymer unit. The lab tests are held regularly and are designed in various ways. Humidity test, fog test, and rain test are some common examples.

Researches believed that polymer insulators were much more cost effective than ceramic insulators. They are able to handle electric loads more than the ceramic predecessor. The design of these insulators allows the device installation or replacement with ease. Moreover, they are more pleasing to the eye in appearance. Mixing and matching them with the interiors of your home is not a bad idea!

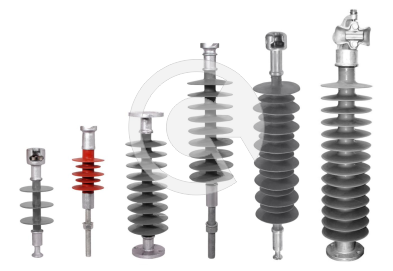

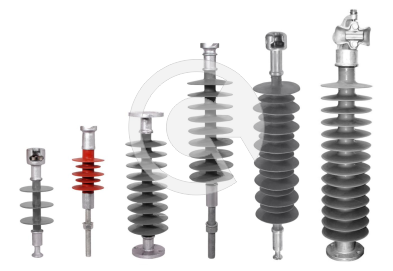

If you are looking forward to install these polymer insulators, you shall look for all the different designs and sizes available in the market. They can be used as a replacement in conventional ceramic products in a variety of environment. The insulators, under proper conditions, can carry a huge load or a tension. They are used on the compression lines, which are commonly found on poles. The insulators are incorporated into phase-to-phase lines that join two lines together and are used for control conductor spacing.

The benefits of polymer insulators

As a replacement over ceramic Insulators, there are some benefits that these polymer insulators offer you, which are mentioned as below:

- No need for zero value check

- Free of cleaning, suitable for difficult maintenance areas, hence economical maintenance.

- Lightweight, economical and easy for transportation and installation

- Not brittle and reduces the purchasing quantities for spare parts

If you are thinking to get polymer insulators, then try searching both online and offline for good deals.

Be the first to comment on "A Briefing On Polymer Insulators"